Complete PCB Assembly Services Across the UK

We are a UK-based electronics manufacturing partner specialising in high-quality PCB assembly for all industries. Whether you need a small batch of prototypes or a reliable long-term production partner, we provide the skills, facilities and technical expertise to meet your requirements.

Our team works closely with design engineers, OEMs and production managers to ensure each build is assembled correctly, efficiently and to the highest standard.

We support turnkey projects, consigned builds and mixed approaches, depending on how you prefer to work.

Printed Circuit Board Assembly in the UK and Ireland

At First Choice Assembly we provide fast, accurate and dependable PCB assembly services for businesses across the UK and Ireland. From one-off prototypes to ongoing production runs, our expert team delivers high-quality assemblies with exceptional attention to detail and consistently short lead times.

Our modern UK facility offers full SMT, THT and mixed-technology assembly, supported by rigorous quality control and a flexible approach to every project.

Get a fast quote today and see how quickly we can bring your design to life.

Book a free consultation

Why Choose First Choice Assembly?

UK-Based PCB Assembly With Fast Lead Times

Our manufacturing facility is located in the West Midlands, giving you the benefits of local communication, short supply chains and rapid turnaround times. We provide a responsive service that overseas manufacturers simply cannot match. You can read more About Our Facility and our advanced manufacturing equipment.

Prototype to Full Production

Whether you're testing a new design or scaling up to regular manufacturing runs, we can support you at every stage. Our flexible assembly lines allow us to provide low-volume prototypes right through to consistent medium and large batch production.

Consistent Quality & High Standards

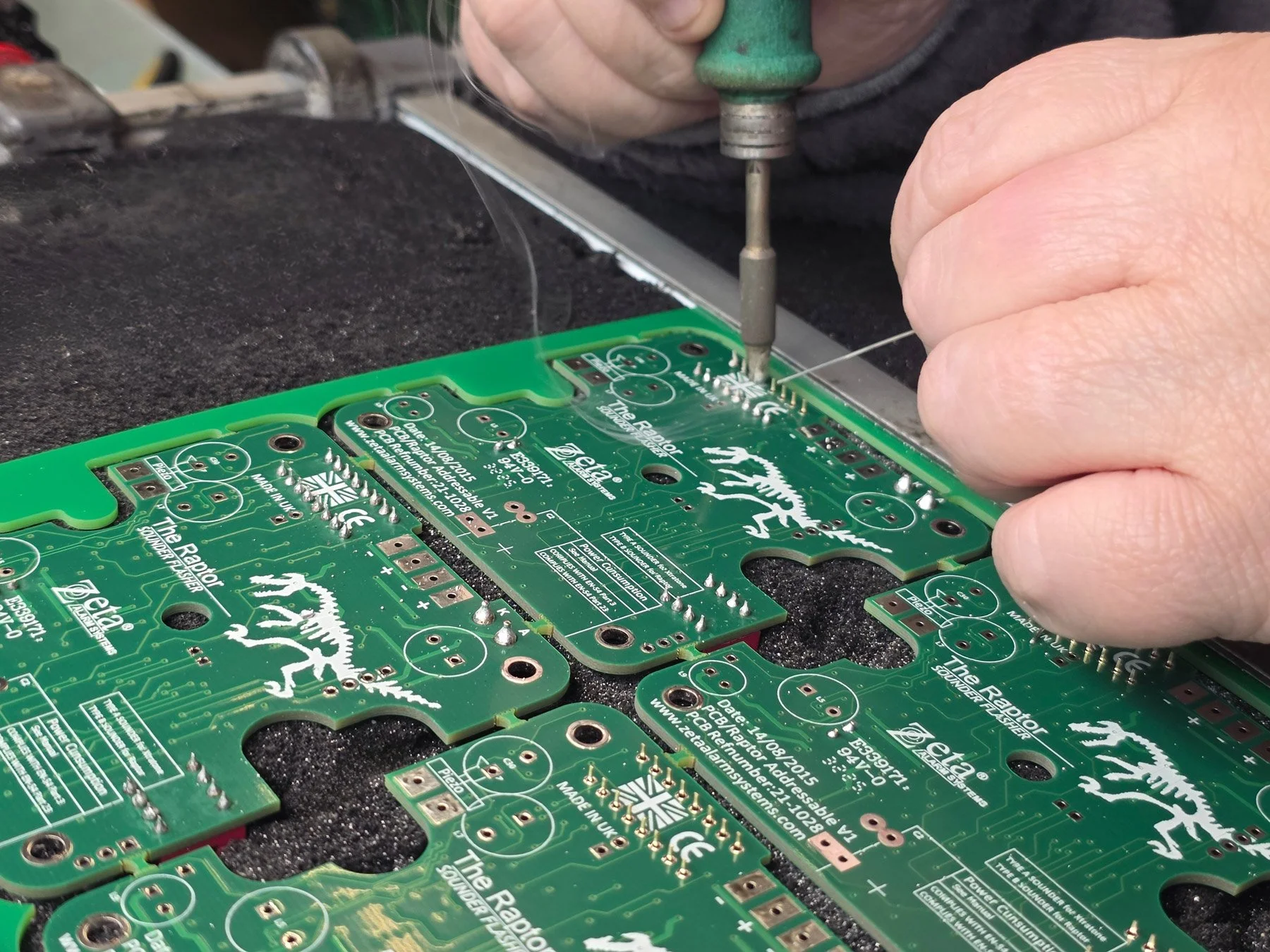

We follow strict quality procedures throughout the entire manufacturing process, ensuring stable performance, precise soldering and reliable long-term operation. Our trained technicians assemble to recognised industry standards, with detailed inspection at key stages.

Flexible Service – Turnkey or Consigned

You can supply your own components or opt for a full turnkey service. We can source parts, manage procurement, check availability and ensure that every component meets your specification and required standards.

Skilled Engineers & Experienced Assembly Technicians

With years of experience in PCB assembly, our team combines advanced technical knowledge with practical manufacturing expertise. We maintain close communication throughout your project to ensure every detail is correct.

See our other services

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

Get in Touch

Our PCB Assembly Process – How It Works

Step 1: Design for Manufacture (DFM) Review

We begin with a full review of your Gerber files, BOM and pick-and-place data. Our engineers check for manufacturability, potential issues and opportunities to improve reliability and assembly efficiency.

Step 2: Component Procurement

If you choose a turnkey service, we source all components from trusted suppliers, ensuring availability, authenticity and full traceability. Alternatively, we can work with your consigned parts.

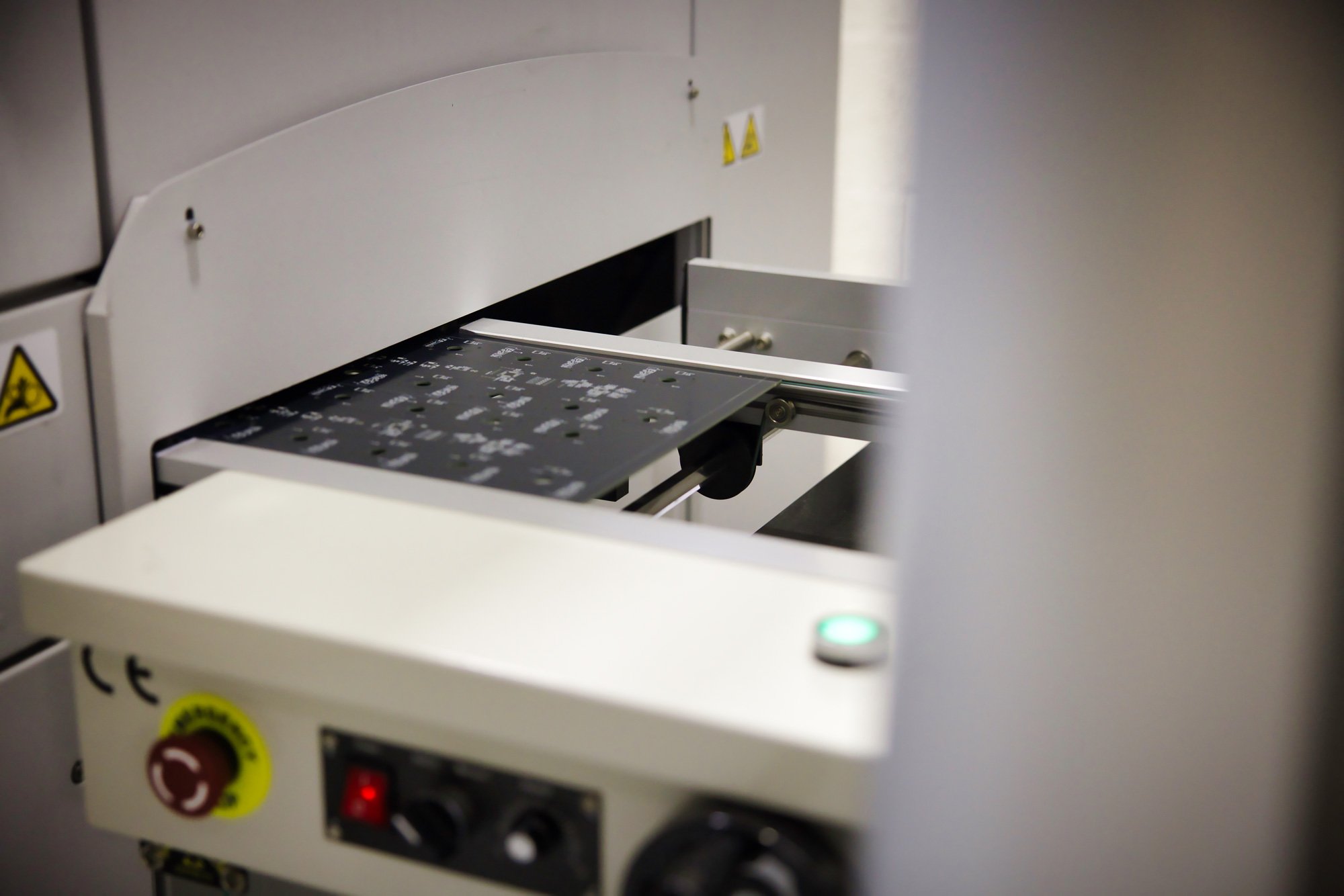

Step 3: Solder Paste Application

Using high-precision stencil printing, we apply solder paste accurately to each pad. This step is crucial for clean joints and long-lasting performance.

Step 4: SMT Pick & Place

Automated pick-and-place machines position components with high accuracy, even for miniature or high-density layouts.

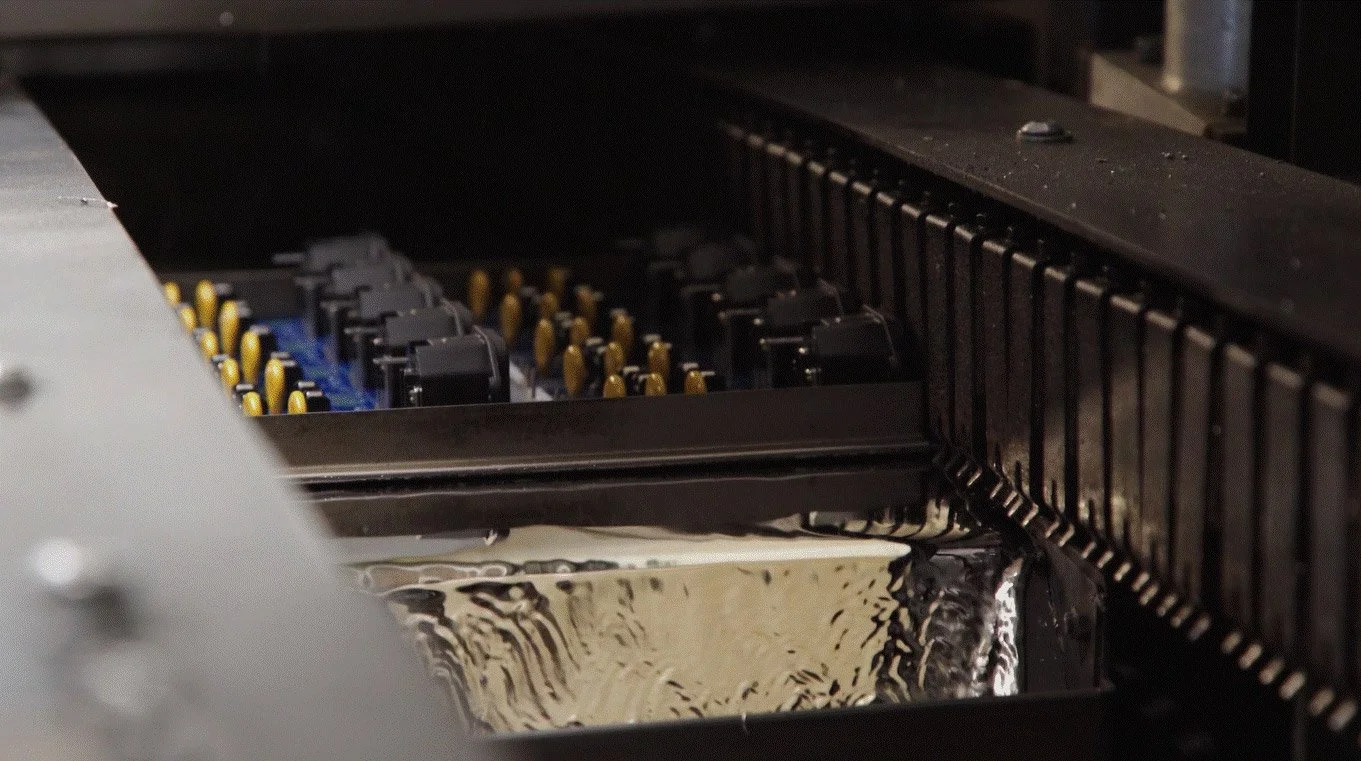

Step 5: Reflow or Wave Soldering

Depending on the assembly type, boards then go through reflow soldering for SMT or wave/selective soldering for THT components.

Step 6: Inspection & Testing

Quality control is built into every stage of our process. We provide:

AOI (Automated Optical Inspection)

X-ray inspection (where required)

Functional testing

Visual inspection by trained technicians

Explore our full PCB Testing & Inspection capabilities for complete quality assurance.

Step 7: Final Assembly, Packing & Dispatch

Completed boards undergo final checks before secure packing and prompt dispatch. We maintain full traceability for consistent quality and repeatable production.

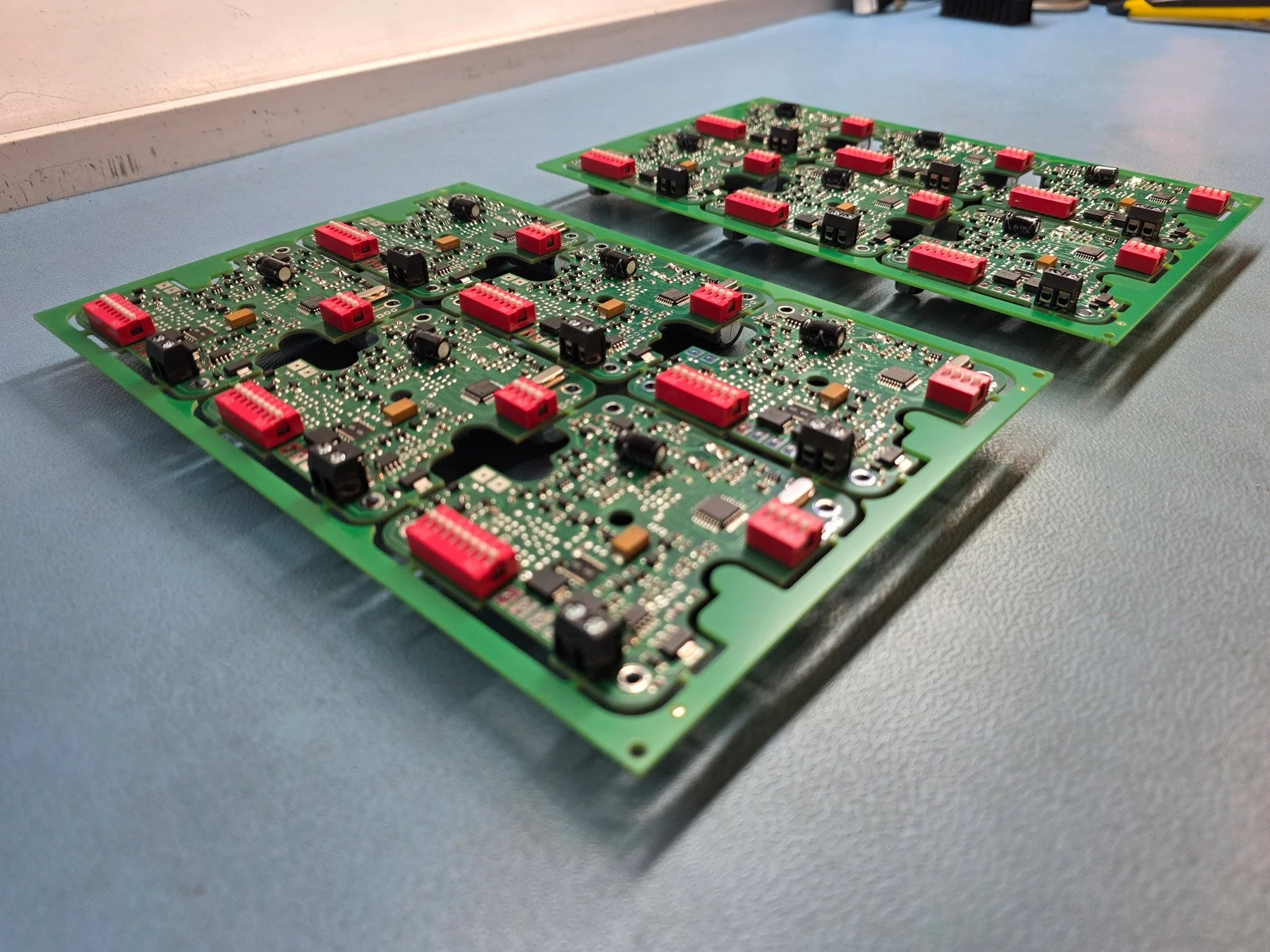

Surface Mount Technology (SMT) Assembly

Our SMT lines support a wide range of component types including fine-pitch devices, micro-BGAs, QFNs and 0201 passives. Automated pick-and-place machines ensure precise placement, followed by carefully controlled reflow soldering for a clean, reliable finish.

To learn more about our SMT capabilities, visit our Surface Mount Assembly service page.

Rigid, Flex and Rigid-Flex PCB Assembly

If your project requires specialist board types, we can assemble rigid, flexible or rigid-flex PCBs depending on your design and performance requirements.

Our PCB Assembly Capabilities

Our facilities are equipped to handle both small and large production runs. We provide:

Through-Hole Technology (THT) Assembly

We offer both manual and automated through-hole assembly, including wave or selective soldering where required. THT is ideal for connectors, high-current components and mechanically robust assemblies.

Find out more about our dedicated Through-Hole Assembly processes.

Prototype PCB Assembly

We specialise in producing accurate, fast-turnaround prototypes that allow you to test, refine and finalise your product before committing to full production.

Learn more about our fast-turnaround PCB Prototyping services.

Mixed Technology (Hybrid) Assembly

For boards that combine SMT and THT components, we provide complete hybrid assembly. Our team ensures every assembly step is sequenced correctly to avoid damage and maintain consistent quality.

Medium to High-Volume PCB Assembly

Our production lines scale smoothly from small batches to larger volume manufacturing, with consistent quality, strict process control and efficient workflow management.

Industries We Serve

We assemble PCBs for a wide range of industries, including:

Industrial automation and control systems

Automotive electronics

Aerospace and defence equipment

Medical and laboratory technology

Consumer electronics and IoT devices

Renewable energy and environmental systems

Our flexible approach ensures we meet the specific requirements of each application, from highly specialised assemblies to robust industrial products.

Benefits of Choosing First Choice Assembly for your PCBs

- High-Speed, Automated PCB Assembly: Advanced equipment for fast and precise component placement.

- Customisable Solutions: We tailor PCB assembly to meet specific project requirements.

- Quality Assurance: 100% inspection with AOI and functional testing.

- Scalable Production: From low-volume prototypes to high-volume manufacturing.

- Cost-Effective Services: Optimised supply chain to reduce costs without compromising quality.

- UK and Ireland: All our assembly takes place in the UK and Ireland for quick turnover.

Testing Methods for Printed Circuit Board Assemblies

Testing is essential to verify that each pcb circuit board assembly performs correctly. We offer:

- In-Circuit Testing (ICT), which checks individual components and connections on the board.

- Functional Testing, where the assembled PCB is tested under real operating conditions to confirm its performance.

By combining different methods, we ensure every pc board assembly is delivered free from defects.

Components: Supplied or Sourced?

A common question is whether customers must supply components for assembly PCB projects. At First Choice Assembly, we can work either way. Clients may supply components if preferred, or we can manage procurement through trusted suppliers. This flexibility simplifies the pcb production and assembly process for many businesses.

PCB Design and Assembly Services

We provide not only pcb assembly service but also pcb design & assembly support. This enables customers to bring new concepts to life, with our engineers ensuring the design is optimised for manufacturability and cost-effectiveness. Having a partner that can handle both pcb fab and assembly shortens lead times and reduces the risk of design-related issues.

Why Choose First Choice Assembly for Printed Circuit Board Assembly?

Choosing the right partner for printed circuit assembly is crucial. We combine technical expertise, advanced equipment and strict quality control to deliver high quality PCB assembly for industries where reliability cannot be compromised.

As a UK-based manufacturer, we provide comprehensive Electronics Assembly Services to support projects of all sizes. Our experience spans industrial control PCB assembly, medical PCB assembly and flexible PCB assembly. With an emphasis on consistency, accuracy and service, we are one of the best PCB assembly companies in the UK for clients who require assembled printed circuit boards that meet demanding standards.

We are more than just a PCB assembly factory, we are a trusted partner who understands the importance of precision, compliance and communication. Whether you require a prototype, a low volume run or full scale production, First Choice Assembly provides a PCB assembly service that delivers on time and to specification.

From Concept to Completion

At First Choice Assembly, we support your project every step of the way. Our skilled team collaborates with you to transform initial ideas into detailed designs, ensuring each PCB meets precise specifications. We handle material sourcing, prototyping, and full-scale assembly in-house, guaranteeing quality and efficiency at every stage.

With rigorous testing and lifetime assurance on all products, we deliver reliable solutions that meet industry standards and bring your vision to life.

Enquire now about PCBs

Full Turnkey Solutions

First Choice Assembly offers complete end-to-end PCB solutions, handling everything from design and sourcing to assembly, ensuring a seamless, efficient process for clients.

Ensuring Quality in PCB Assembly

Quality is fundamental in the pcb assembly industry. At First Choice Assembly we work to IPC standards for pcb assembly, which define best practices for soldering, cleanliness, component placement and acceptance criteria. This ensures our clients receive only high quality pcb fabrication and assembly.

We apply process controls at every stage, from incoming material checks to final functional testing. Our BSI ISO9001:2015 quality management system provides complete traceability, giving clients confidence in both the product and the process.

Check our Certificates

Quality, Compliance & Traceability

Quality is central to everything we do. Our processes are built around consistent inspection, rigorous testing and careful handling of every board and component.

We work to recognised industry standards and maintain strict control of materials throughout the assembly process. Every batch is traceable, and all components are sourced from trusted suppliers to ensure authenticity and reliability.

Our focus on quality ensures every finished PCB performs exactly as intended.

Bespoke Design In-House

First Choice Assembly’s expert team provides custom PCB designs tailored to unique project specifications, bringing flexibility and precision to every build.

Lifetime Assurance

Our commitment to value is backed by a lifetime warranty against manufacturing defects. Underscoring our commitment to quality and providing long-term reliability for all manufactured products.

PCB Assembly FAQs

We've gathered the most common questions here to help you understand our capabilities, processes, and standards. From lead times to technical specifics, our FAQs cover everything you need to know to get started with First Choice Assembly.

If you don’t see your question answered here, feel free to reach out, and our team will be happy to assist.

-

PCB assembly is the process of mounting electronic components onto a printed circuit board to create a complete, functioning electronic unit.

-

We typically require your Gerber files, BOM, pick-and-place data (if available), and the quantities you’re looking to build.

-

Yes. We specialise in fast-turnaround prototypes to help you move quickly from concept to testing.

-

Lead times depend on component availability and complexity, but we offer highly competitive turnaround times for both prototypes and production runs.

-

Yes. Our turnkey service includes full component procurement from reputable suppliers with full traceability.

-

Absolutely. We support single prototypes, small batches and full production quantities.

-

Our assemblies follow industry-recognised quality and workmanship standards, including IPC guidelines.

-

Yes — we supply PCB assemblies nationwide, including Northern Ireland and the Republic of Ireland.

Get a Fast Quote for PCB Assembly

Whether you have a single prototype or a full production run, we’re ready to help. Simply send your Gerber files, BOM and required quantities and our team will return a competitive quote as quickly as possible.

Contact us today to get started.